“I wanted to add some Yale Blue to the steam,” Cox tells me, “but the managers didn’t want to call attention to ourselves.”

Jeremy Cox, the Sterling Power Plant manager, gestures towards three exhaust pipes, each jutting around six stories towards the sky. One pipe is frosted with cream ornamentation; the others are twin steel limbs. They churn out an invisible cloud of billowing emissions, as they do every day, all year. The red-bricked buildings of the Sterling Power Plant, scattered at the base of the pipes, emit a loud growl that can be heard from around the block. Intermittently, a raucous clang or hiss sounds from an appendage of the building, but the noise dissipates before I can determine its source.

Cox is poised by the door to the underground plant, peering out from under his yellow hard hat as I fumble with a notebook and pen. I mention the bestial noises to Cox, but he appears to barely register the clamor. Once he ushers me inside, we walk down a hallway lined with snaking pipes and diagrams of turbines. If not for the Yale bulldog logo on his hoodie, it would be difficult to remember that we’re less than half a mile away from the ivy-draped buildings of campus.

The Sterling Plant powers the Yale School of Medicine and the Hospital. It’s one of two plants on Yale’s campus, the other being the Central Power Plant that operates on Grove Street. They’re easy to miss: neither is marked with signposts nor touted from the outside for powering the University. Cox told me about the University of Alaska adding a light show with their school’s colors to their power plant, but Yale seems intent on keeping its plants hidden from the public eye.

With revamped exteriors, it is difficult to tell that the Central Power Plant and Sterling Power Plant were built in 1918 and 1923, respectively. But on cold days, the steam pouring from the gothic-style exhaust stacks resembles the ashen clouds of a coal-fired plant, a scene straight out of a photograph of early industrial America. The plants’ unassuming appearance conceals a history of harmful practices from the passerby’s eye—a legacy of slow-paced improvement, of Yale disregarding employee health and student wellbeing, swept into coal-dusted shadows.

The Endowment Justice Coalition publicized the extent of Yale’s investments in fossil fuels in 2021—an estimated 800 million to 2.5 billion dollars; it’s hard to know for sure due to a lack of transparency. Unlike Yale’s investment practices, the power plants haven’t been held to the same level of scrutiny. While the full tale of Yale’s energy infrastructure can only be traced through obscure financial documentation and lessons in thermodynamics, the consequences are tangible to us all, even if they’re easy to ignore—flip the light switch or turn on the hot water, and you’re consuming fossil fuels. As universities across the country are forced to reckon with global calls for cleaner energy generation, Yale will have no choice but to reconsider its priorities and role as a research university, not a hedge fund with a school attached.

If the power plants tell us one thing, it is that transformations in Yale’s energy infrastructure aren’t simple, fast, or necessarily effective. Yale’s energy history—from the first, cursory dappling of coal-fired plants to modern renewables projects—is patched together with stories of belated improvement and myopic preparation, especially to the impact their efforts have on surrounding communities. We now stand on the cusp of yet another inflection point in energy history. As we once again entrust Yale to responsibly steward an update of on-campus energy infrastructure, it is more important than ever to understand the full scope of power the University possesses when it comes to energy production, how it’s leveraged that power in the past, and the human consequences that are too often taken as secondary to ‘progress.’ There may be no better way to do so than to look to the exhaust pipes of the Yale power plants.

If the power plants tell us one thing, it is that transformations in Yale’s energy infrastructure aren’t simple, fast, or necessarily effective.

Early in Yale’s history, the University’s method of generating electricity frustrated campus residents. Before the Central Power Plant was constructed, several smaller plants burned coal to heat and light buildings. These plants—scattered near classrooms and below dining halls—left campus cloaked in black soot.

Yale paid little attention to complaints as the issue of coal ash lingering near living spaces became exacerbated in the 1910s. Students and faculty were at risk of incurring chronic respiratory irritation and exposure to a rank, sulfurous compound that burnt coal releases. “The value of the plant from a hygienic standpoint cannot be computed in dollars and cents,” a 1911 Yale Daily News article reads. “Pure air in our dormitories and lecture rooms is a consideration not to be forgotten.” It was only when the University planned on expanding its operations with the construction of a new dormitory that the inefficient system of the smaller plants was called into question. Donations eventually enabled the construction of the Central Power Plant in 1918, a symbol of Yale’s self-sustainability, and its growing power as an institution.

In addition to spewing noxious coal dust around campus, the new plant threatened the safety of its workers attending to the outsized operations, driving employees to strike for higher pay in 1941. “They had the proverbial coal man working then who would shovel coal into the furnace,” said Cox, “They were constantly breathing in that coal dust.” The coal dust particles, smaller than one-thirtieth the width of a human hair, meander into the lungs and bloodstream where they can cause a host of chronic lung, heart, brain, and nervous system diseases. The plant clearly wasn’t built to address the concerns about student or employee health.

As we walked through the power plant’s underbelly, Cox mentioned that he had worked in a coal-fired plant for a short while, prior to his job at Yale. Running his hands along some pipes sealed with nuts and bolts, he said, “If the seals weren’t perfect, I would breathe in all these coal particles—I’m healthy now, but who knows what I might come down with in the future.”

Cox showed me the old furnace, power washed but still stained with a black hue. His flashlight illuminated a mummified pigeon at the bottom of the cavern and we lingered there, silent, in the macabre scene. “Sometimes I wish I could see what it was really like back then,” he said, before being interrupted by his cell phone’s ringtone: the sound of a Star Wars lightsaber unsheathing.

His flashlight illuminated a mummified pigeon at the bottom of the cavern and we lingered there, silent, in the macabre scene.

In the 1940s, Yale’s Central and Sterling plants burned through 35,000 to 40,000 tons of coal annually, the weight of the Statue of Liberty. A Yale Daily News article from 1953 describes how the clock hands of Harkness Tower were barely visible through the power plant “smaze”— a mixture of smog and haze spewed by the plants’ smokestacks.

From the 1940s to the early 2000s, Yale consistently struggled to meet Connecticut’s baseline air pollution regulations. Yale attempted to clean up its act by weaning off coal, but in doing so became completely reliant on natural gas, a colorless and odorless fossil fuel that was burned alongside coal in the plants since the 1910s. In the 1960s, Yale managed to cut its power demands by ten percent, and in the decades after tweaked existing machinery to further lower emissions. But, by 1992, Yale’s Senior Energy and Environmental Engineer declared that the plants were still not meeting the state’s air pollution standards.

Yale’s slow progress isn’t necessarily surprising. It’s risky for a campus to experiment with new energy technologies. Lab spaces, classrooms, and dorms could all go dark without large, consistent stocks of energy, which is not something the University would leave to chance. Even during short outages caused by union strikes in the 1950s, campus life was disrupted as undergraduates took up maintenance duties on campus. It wasn’t until 2007— when Yale replaced old machinery with a turbine able to concurrently produce hot steam and electricity, a setup called cogeneration—that Yale met state codes.

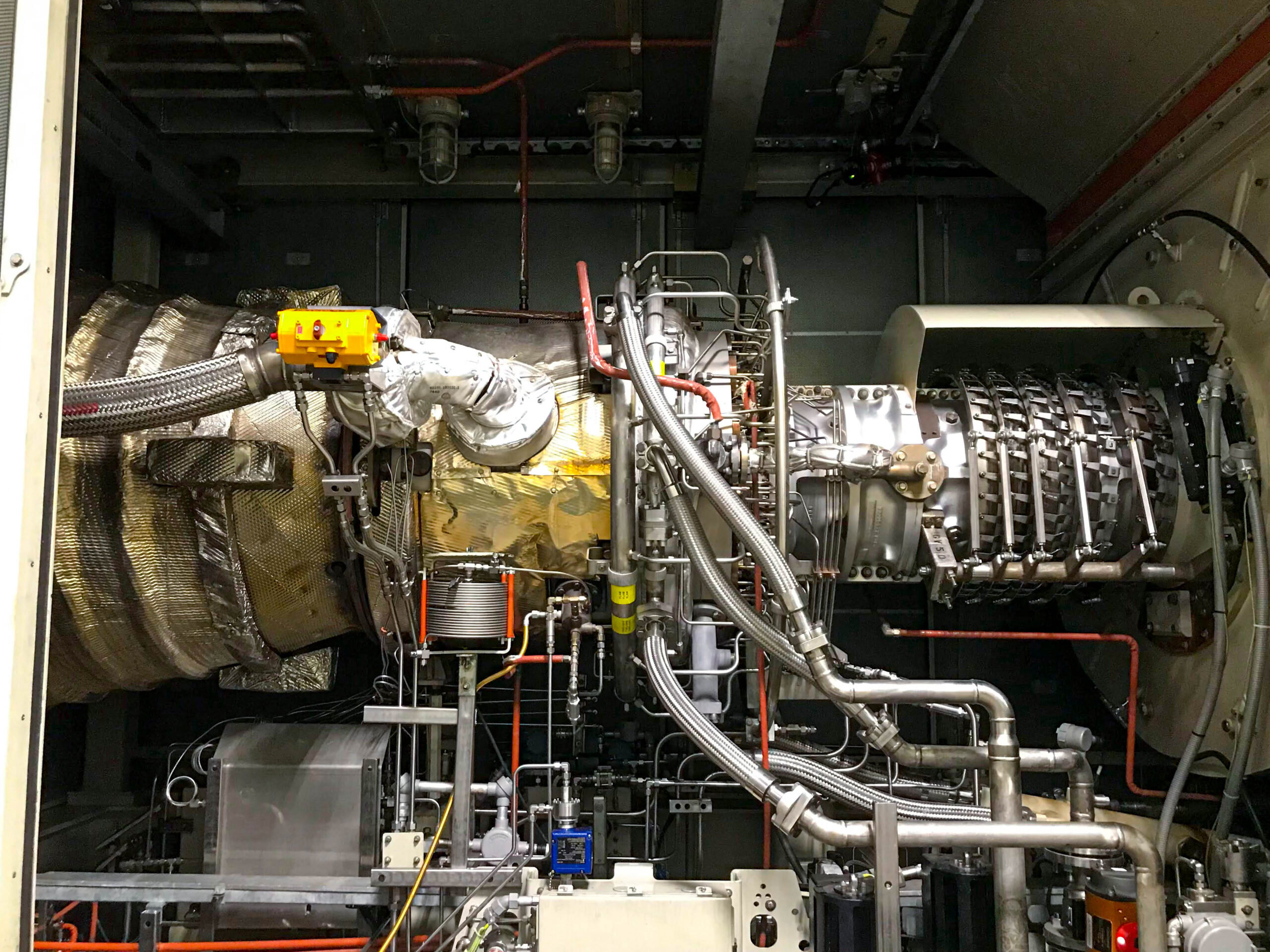

The cogeneration setup is impressive to behold: studded with windows revealing hot blue gas, it spans the length of a large bus. I don a hard hat and earplugs before Cox leads me to the gas turbine and opens the metal double doors. Out belches oil-smelling fumes and a booming clamor that sounds like a plane continuously taking off. “It’s like a big gas-powered grill on its side attached to a jet turbine engine,” yells Cox.

Cogeneration was the main cause of the 43 percent reduction of Yale’s greenhouse gas emissions from 2005 to 2020. In a typical power generator, heated steam spins a large fan-like turbine and exits the smokestacks in 1200°F plumes. Cogeneration captures the warm steam, recycling its energy before letting out a cooler 300°F stream through the pipes. Yet, the technology isn’t revolutionary. Cogeneration first appeared in early 20th century American power plants and was only adopted in industrial plants after it was promoted as an energy-efficient technology in the 1978 PURPA act. Yale adopted the technology around the time other American universities got on the bandwagon.

The time has come again for Yale to consider revamping its energy infrastructure.

Each year, the exhaust pipes still release 198,000 metric tons of greenhouse gasses, the weight of the Sears Tower. “Natural gas is not the panacea,” stressed Kenneth Gillingham, Professor of Economics at the Yale School of the Environment.

If the emissions themselves weren’t harmful enough, there is the matter of how Yale sources their natural gas. Yale is the largest consumer of Southern Gas Connecticut (SGC)—the father company of which, Enbridge, was responsible for one of the country’s largest oil spills in 2010, and has been met with popular and governmental backlash for its destructive fracking practices. Yale’s ties to Enbridge can only be found with incessant digging through financial records and obscure documentation—it’s a well-kept secret. While Yale leverages Enbridge’s resources to power campus, it shrouds its behavior in greenwashed rhetoric. “In my day, they were called smokestacks,” Cox tells me. “Now, there’s a bit of a PR campaign to make it sound a lot cleaner. So exhaust pipes it is.”

Not only does the University mask how it sources its natural gas, Yale also isn’t contractually allowed to sell the power it generates. The result: Yale operates on an isolated microgrid with its two plants releasing nearly fourteen times more greenhouse gases than the nearest energy facility in New Haven. “Yale had this idea early on and was like, you know what, we should create our own power,” said Cox, emphasizing the last part in a booming voice. This leaves the University in complete control of its operations: Yale can choose what type of fuel to use, doesn’t need to negotiate pricing with energy companies, and can produce however much energy it wants. Yale’s historical self-sustenance is what let the plants emit fossil fuels emissions above state pollution standards in the 2000s: its older plants weren’t expected to comply with modern standards. It also will keep the University safe during widespread outages caused by storms and the city of New Haven dependent on Yale energy. By isolating itself from the grid, Yale has continued to keep its resources within the University and its power consolidated.

The time has come again for Yale to consider revamping its energy infrastructure. The Biden administration has cracked down on natural gas processing facilities and Governor Ned Lamont promises that Connecticut will be carbon-free by 2040. The 2021 Yale Sustainability Progress Report announces Yale will use “emerging technologies” like geothermal heat and green hydrogen fuel to be carbon-free by 2050, but progress has been slow and largely underwhelming.

Over the past decade, Yale installed geothermal-powered heat pumps at Kroon Hall, the School of the Environment’s central hub. These pumps reach 1,600 feet down to Earth’s warmer core in order to heat water into steam. “Only one heat pump out of three really works,” said Gillingham. “Even if the pumps did work, they only provide heat, not electricity, so they couldn’t replace the power plant’s cogenerating beast.”

Yale could supplement heat pumps with a renewable source of electricity from one of their many pilot projects—the fleet of ten micro wind turbines purchased by Yale in 2009, for example. These turbines sit atop Becton, an engineering and applied science building on campus, and attempt to demonstrate Yale’s venture into renewables. But the ten fans, which look like miniplane rotors, only provide half a percent of the building’s annual electricity needs. “As windy as it feels on Science Hill, it’s really not a great resource for producing a lot of electricity,” said Gillingham.

The readiness and cost of greener technologies aside, it is clear that change is impending and Yale will need to do a better job informing its operations and attitudes with the health and safety of surrounding communities.

Yale has attempted to think bigger by quietly investing 102 million dollars in a wind farm company’s project to crown Maine’s hilltops with a crop of gargantuan, white windmills. But the approach, spearheaded by the late David Swensen, hasn’t run over smoothly with locals. “We’re defending our way of life. We’re defending the people, our livelihood, our culture,” commented Lindsay Wheaton, the owner of the Grand Lake Lodge, whose wilderness retreat property sits facing the ridge lined with windmills. Other residents expressed concern about the project’s impact on the fragile mountain slopes of Roxbury. It appears the project has been canceled, though no definite reason is given, and it is unlikely that it will serve as a blueprint for Yale’s energy production anytime soon.

Other universities on the east coast, a region without a bounty of local solar and wind farms, are facing similar problems in finding large-scale solutions. In 2021, Harvard constructed a natural gas-burning cogeneration plant with a chic modern facade, much to the annoyance of climate activists. When I asked Cox his opinion on wind farms, he noted that Yale and other older colleges don’t yet have the infrastructure for a large electrical grid. “There are options, but everything’s expensive,” added Gillingham. Yale’s sizable endowment could help develop these technologies, such as refitting the existing plants with hydrogen fuel to thwart emissions, utilize existing facilities, and keep jobs in New Haven.

The readiness and cost of greener technologies aside, it is clear that change is impending and Yale will need to do a better job informing its operations and attitudes with the health and safety of surrounding communities. After a century of owning its means of energy production, the University still struggles to properly prepare for impending changes – caught flatfooted when the need for transformation becomes unavoidable – or realize the full scope of its facilities’ impact on people. When a repair worker fell into the Central Power Plant’s chimney to his death in 2015, the Yale deputy press secretary closed out the press release with the statement: “Power to campus buildings was not affected.”

As the University is called to participate in the next stage of the transition to cleaner energy, the essential question remains: can we trust that Yale will use its power responsibly?

I walk back to campus from the corner of Congress Ave and Frontage Road and the power plant hums behind my back. Above the passing traffic of students and cars, vapor drifts from the towering exhaust pipes and disperses over campus. Hiding a beast in plain sight is no small feat, but Yale’s power makes it both possible and profitable.

— Saachi Grewal is a senior in Pierson College.